Think Your Suppliers Are Reliable? Better Double-Check

Your inventory might be organized, but are your suppliers slowing you down? Learn how to audit vendors before they become your biggest liability.

Published under The Inventory Hat on HatStacked.com

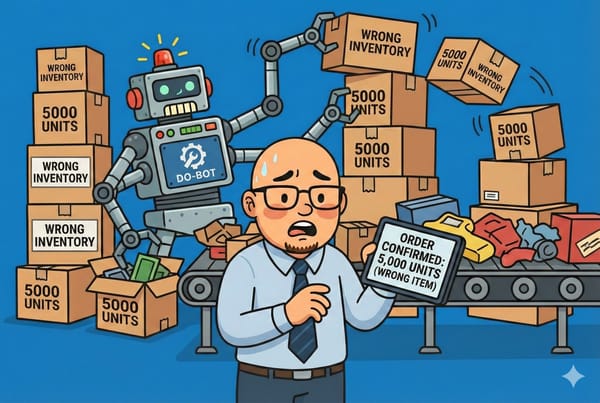

Your inventory spreadsheet looks tight. Everything’s labeled, scanned, shelved, and color-coded. But your suppliers? That’s another story. This guide is about cleaning up their mess before it becomes yours.

First, Let’s Admit Something: Most Suppliers Are Not Organized

We love them. We need them. But some of them couldn’t track a package with GPS and a bloodhound.

And when their chaos becomes your chaos? That’s when your customers start emailing things like “where is my order” and “I will be leaving a review.”

Step 1: Actually Look at Their Track Record

You probably know who your best vendors are. But do you know know?

Pull up:

- On-time delivery rates

- Backorder frequency

- Price creep history (looking at you, 11% hike in Q2)

- Packaging quality (are they shipping with newspaper and prayers?)

Give them a report card. Bonus points if you use stickers.

Step 2: Check Their Certifications (AKA Are They Still Legit?)

Things change. That ISO cert from 2020 might be dust now.

Ask for:

- Updated certifications

- Current insurance docs

- A point of contact who hasn’t vanished into the ether

If their quality control team is now “just Dave,” it’s time for a conversation.

Step 3: Pretend You’re the Customer and Place a Test Order

Yes, really.

Order something from their catalog as if you were a customer:

- Was it packed right?

- Did it arrive when they said it would?

- Did it smell like sadness and warehouse funk?

You might learn more in one sneaky order than 50 emails.

Step 4: Have a Real Talk About Lead Times

You: “Can we count on 3 days?”

Them: “Probably.”

Translation: “We hope so, but Tim is on vacation and Susan’s printer exploded.”

Ask for:

- Lead time guarantees

- Realistic fulfillment windows

- What happens when they miss the mark

You need honesty more than optimism. Optimism doesn't restock your shelves.

Step 5: Demand an Inventory Statement (Yes, Like It’s 1999)

Ask what they actually have in stock. Not what they hope to have. Not what’s on the way. What’s in their warehouse right now.

If they don’t know? That’s your red flag waving in HD.

Also: if their inventory is in spreadsheets named “FINAL_FINAL_USE_THIS_ONE,” get ready to build buffer stock.

Step 6: Audit Their Communication Style

- Do they respond to emails before you forget you sent them?

- Can you call someone who actually answers the phone?

- Do they notify you about delays before your customer does?

If they use smoke signals or only respond after the third “just circling back,” downgrade accordingly.

Step 7: Build a Tier System (Gold, Silver, Oh No)

Not all suppliers are equal. Don’t treat them like they are.

Try:

- Gold = Reliable, transparent, easy to work with

- Silver = Good enough, but needs reminders

- Oh No = Ghosts you until there's a problem

Then shift volume to the ones who keep your blood pressure low.

Step 8: Replace the Worst Before They Replace Your Sanity

Some vendors are too costly to keep. Not just in price, but in time, stress, and reputation damage.

When it’s time, make a clean cut:

- Download your history

- Move your business

- Send a polite “we’re parting ways” email

- Celebrate with a snack

You’ll never regret replacing a supplier who gives you more excuses than shipments.

Final Thought

Your suppliers may not show up on your P&L as “stress factors,” but they should.

Because when they mess up? You’re the one refunding, apologizing, and explaining why the order didn’t ship.

Audit them now. Before your customers audit you.