The Inventory Shrinkage Problem You’re Pretending Isn’t Happening

Shrinkage isn’t just a retail buzzword. It’s quietly draining your profits, one missing SKU at a time. Here’s how to find it, fix it, and stop pretending it’s not happening.

Published under The Inventory Hat on HatStacked.com

You didn’t see it happen. You didn’t sell it. But somehow... it’s gone. Welcome to the magical world of inventory shrinkage, where products vanish without a trace and your bottom line quietly weeps in the corner.

What Even Is Shrinkage (and Why Should You Care)?

“Shrinkage” is just a fancy word for missing stuff. It’s what happens when your physical inventory doesn’t match what your system says you should have.

Sometimes it’s theft. Sometimes it’s damage. Sometimes it’s a miscount, a misplacement, or a mystery only solved by time travel.

But always, it means money out the door.

Shrinkage = lost profit.

And if you’re not tracking it, you’re letting it happen on repeat.

Small Businesses Think They’re Immune (You’re Not)

We hear this a lot:

- “We’re too small for that to be a problem.”

- “I trust my team.”

- “We don’t have a warehouse, so it’s easy to track.”

- “It’s probably just a miscount.”

Maybe. But even small operations are vulnerable, especially small ones. When you wear every hat, it’s easy to miss the slow leak in the background.

Shrinkage doesn’t usually show up with flashing lights. It shows up as:

- Reordering faster than expected

- Orders you can’t fulfill

- Mismatched end-of-month counts

- Employees frustrated that “things just aren’t where they should be”

Where Your Inventory Really Goes

Let’s break it down.

1. Theft (Yes, Even in Your Sweet Little Shop)

Internal theft is real. External theft is even more so if you’ve got a physical location.

It’s not always malicious. Sometimes it’s a free snack that “doesn’t count.” Sometimes it’s an extra item tossed in with an order “as a surprise.” But it adds up.

2. Damage (a.k.a. the Box Was Already Like That)

Things get dropped. Boxes tear. Products break. And if no one logs it? It disappears from your count like it was never there.

3. Misplacement (It’s in the Wrong Bin. Again.)

This is the kind of shrinkage that makes you question your grip on reality. The item exists, but it’s just not where it’s supposed to be.

Congrats. You’ve got Schrödinger’s inventory.

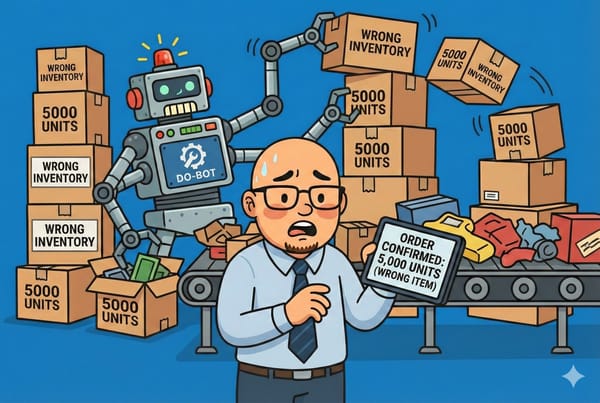

4. Poor Receiving Practices

If you don’t double-check shipments when they arrive, you might be missing items before they ever hit the shelf. And if your system auto-adds based on the packing slip? You're living in a fantasy.

5. Paperwork Errors and Phantom SKUs

Manual entry is a beautiful way to create chaos. Miss a digit, miscount a case, or duplicate a product code and boom... you’ve got ghost inventory.

How to Know If Shrinkage Is Happening

Look for signs:

- Your “on hand” numbers feel wrong

- You keep refunding customers for out-of-stocks

- Your physical count never matches your spreadsheet

- Employees are quietly restocking behind your back

- You reorder things and then find them later, hiding

If it feels like your inventory is gaslighting you, it probably is.

So What Can You Actually Do?

1. Do Regular Physical Counts

We know... it’s boring. But you can’t fix what you don’t track.

Start with cycle counts:

Count one section of inventory each week instead of everything at once. Less painful, more frequent, way more useful.

2. Log All Adjustments

Train yourself and your team to write it down. Every break, every sample, every suspiciously crushed box. Log it. If you wouldn’t sell it, it shouldn’t be counted.

3. Use Barcodes or SKUs — Seriously

Even a basic system like Sortly or Zoho Inventory can help you assign and track items properly.

Related: Inventory Tracking for People Who’d Rather Be Doing Literally Anything Else

4. Revisit Your Receiving Process

Double-check what you get. Don’t let your system mark everything as received just because UPS dropped it off. Humans make mistakes as do machines.

5. Install the Cheapest Security You Can

Cameras don’t have to be expensive. Even a $30 smart cam over your receiving table helps if something weird keeps happening.

Not to spy. Just to document.

What to Do If You Discover a Problem

If It’s a Pattern:

- Run a report on affected items

- Look at who handles that stock

- Review the workflow

Don’t assume malice, but don’t assume innocence either. Fix the system, not just the symptoms.

If It’s a One-Off:

- Adjust your count

- Add a log entry

- Move on, wiser

Shrinkage Is Quiet, but It’s Not Harmless

You won’t notice shrinkage on any single order. But over time, it hits:

- Margins

- Fulfillment rates

- Employee trust

- Customer experience

It’s death by a thousand misplaced SKUs.

Final Word

You don’t need a warehouse management system or a barcode scanner shaped like a gun to beat shrinkage.

You just need:

- Eyes on your inventory

- A consistent process

- A healthy dose of suspicion

- A spreadsheet that isn’t lying to you

Shrinkage might be normal, but that doesn’t mean it’s acceptable.

Start tracking it. Call it out. And stop pretending it isn’t happening.