Master Your Stock: Essential Year-End Inventory Planning for Small Business Inventory Management in 2026

The Inventory Hat is dusty, smells like cardboard, and forces you to confront that pile of unsold widgets from March. Stop guessing your numbers for the IRS and start mastering your stock with our jargon-free year-end guide.

If you are reading this, congratulations. You survived the holiday rush.The last-minute shoppers have finally retreated to their caves to hibernate. The wrapping paper is filling up the recycling bin. You are likely currently vibrating from a dangerous combination of exhaustion, adrenaline, and excessive caffeine intake.

Welcome to the weirdest week of the year. That strange, liminal space between Christmas and New Year’s where time has no meaning, nobody knows what day it is, and eating cheese at 11 AM is socially acceptable.

For normal people, this is a time to nap. For you, the lucky owner of a small business, this is the time for the Inventory Hat.

The Inventory Hat is dusty. It smells like old cardboard and packing tape. It is the hat that forces you to look at a pile of unsold widgets in the dark corner of your warehouse and ask yourself, "Why did I buy 500 of those in teal? Who hurt me?"

As we stare down the barrel of 2026, inventory management isn't just about counting boxes so the IRS doesn't audit you (though, let’s be honest, that’s a big part of it). It’s about figuring out where your cash went in 2025 and how to get it back in 2026.

Your inventory is likely your biggest asset. It’s also your biggest liability. It is literal stacks of cash sitting on shelves, gathering dust, and occasionally getting crushed by a forklift.

So, grab a clipboard, put on your most comfortable shoes, and let’s master your stock. Here is the honest guide to year-end inventory planning that will set you up for a profitable 2026.

Section 1: The "Why" (Or: Why Can't I Just Guess?)

I know what you’re thinking. You’re standing in the doorway of your storage room, coffee in hand, thinking, "Josh, I can just eyeball it. It looks like... about $50,000 worth of stuff. Maybe $55,000 if I count the stuff under the desk."

Stop it. Put the "Guessing Hat" away. That hat is expensive.

Year-end inventory planning is the bedrock of your business’s financial reality. If you screw this up, you screw up your taxes, your cash flow analysis, and your ability to sleep at night.

1. The Tax Reality (The COGS Equation)

Let’s talk about the IRS. They are the uninvited partner in your business who takes a cut of the profit but never helps you tape up boxes or deal with angry customers.

The IRS doesn't tax you on what you bought. They tax you on what you sold. To figure out your profit, you have to calculate your Cost of Goods Sold (COGS). The formula looks simple, but it's a trap:

Beginning Inventory (Jan 1, 2025) + Purchases (2025) – Ending Inventory (Dec 31, 2025) = COGS

See that "Ending Inventory" variable at the end? That is the number you are about to count. If that number is wrong, your COGS is wrong. If your COGS is wrong, your Net Income is wrong.

- Scenario A: You overestimate your ending inventory. You tell the IRS you have more assets than you do. Your COGS goes down, your profit goes up, and you pay more taxes on phantom money you don't actually have. Congratulations, you played yourself.

- Scenario B: You underestimate your ending inventory. Your COGS goes up, your profit goes down, and you pay less tax. Sounds great, right? Until you get audited three years from now, and the agent asks why you claimed you sold 10,000 units when you clearly still have 5,000 of them sitting in your garage.

Accuracy isn't a "nice to have." It's a "stay out of jail" card.

2. The Cash Flow Reality (Dusty Money)

Small businesses rarely die because they lack profit on paper. They die because they run out of cash.

When you look at your shelves, I want you to stop seeing products. Stop seeing "Vintage Style Coffee Mugs." Start seeing stacks of $20 bills wrapped in bubble wrap.

- That box of expired trendy gadgets from 2023? That’s a stack of money you lit on fire.

- That pallet of raw materials you haven’t used? That’s money you could have used to pay yourself, but instead, it’s acting as a very expensive paperweight.

Year-end planning is the only time you get a true, unfiltered look at your Liquidity. You need to know exactly how much of your capital is frozen in stock so you can plan your 2026 budget. You can't pay your rent with "potential sales." You pay it with cash.

Need a refresher on why cash is king? Read Cash Flow for People Who Think Spreadsheets Are a Personality Type.

3. The 2026 Baseline

If your 2025 closing data is garbage, your 2026 starting data is garbage. You cannot calculate turnover rates, forecast demand, or spot theft if your baseline is built on "eh, looks like about a hundred units."

We are wiping the slate clean. We are drawing a line in the sand. 2026 is the year we stop guessing.

Section 2: The Great Physical Count (The "Wall-to-Wall" Nightmare)

There is no app that fixes this. There is no AI that can physically crawl behind your shelving unit to find the box that fell back there in March. You have to count.

This is known as the Wall-to-Wall Count. It is tedious. It is boring. It is essential.

Phase 1: The Pre-Game Prep (Do This Now)

Do not wait until December 31st at 11:50 PM to start. That is a recipe for a drinking problem.

1. The "Clean Up" Operation

Two days before the count, go into your storage area. If it’s a warehouse, a back room, or your basement... tidy it up.

- If a box is open, tape it shut.

- If a pallet is leaning dangerously, fix it.

- The Golden Rule: Ensure every single item has a visible SKU or barcode. If you find a mystery box with no label, identify it now, not when your team is tired and hungry during the count.

2. Map Your Space

Draw a map. Seriously. Label your shelves, racks, and floor zones. "Zone A, Shelf 1." "Zone B, The Pile in the Corner."

Assign specific people to specific zones. If you don't do this, two people will count the same shelf, and nobody will count the bathroom supply closet where you stored the extra inventory during the Black Friday panic.

3. The Tools

Do you have clipboards? Do you have pens that actually write? Do you have count sheets?

- HatStacked Tip: Print count sheets that list the SKUs supposed to be in a location, but DO NOT print the quantity your computer thinks is there. If the sheet says "10," your employee will glance at it, see "about 10," and write 10. If the sheet is blank, they actually have to count. This is psychology 101.

Phase 2: The Freeze (The Critical Window)

You cannot count a moving target. This is the hardest part for active businesses, but you have to do it.

1. Stop Receiving

Cut off inbound shipments 24 hours before the count. If a UPS truck shows up during the count, take the pallet, wrap it in shrink wrap, slap a giant sign on it that says "DO NOT COUNT - POST DEC 31", and shove it in a quarantine zone.

2. Stop Shipping

Ideally, you do your count when you are closed. If you run a 24/7 e-commerce operation, you need to pick a cutoff time. Any order placed after 5:00 PM on the 31st gets fulfilled after the count is done. The inventory leaves the building physically only after it has been counted.

Phase 3: The Count Party

If you have employees, you need to bribe them. This is not optional. The industry standard exchange rate is Pizza and Beer (or fancy soda for the under-21s).

- The Tag Method: Use two-part tags or sticky notes. One person counts a bin, writes the number on the tag, and sticks it on.

- The Audit: You (The Boss) walk around. You don't count everything. You spot-check. Go to a bin that says "52." Count it. If it’s 52, great. If it’s 48, find the person who counted it and ask them if they need glasses or more coffee.

- The Weird Stuff: You will find things. Broken things. Things you stopped selling three years ago. A half-eaten sandwich from July. This is the time to separate the Sellable from the Damaged/Obsolete. Do not count broken items as good inventory. Write them off.

Section 3: The Analysis (The "What is This Crap?" Phase)

You have the numbers. You are tired. You smell like dust. Now comes the part where you put on the Operations Hat and hurt your own feelings with math.

We need to categorize your inventory into three buckets. This is often called the ABC Analysis, but I prefer to call it The Good, The Bad, and The Ugly.

Bucket A: The Winners (The 80/20 Rule)

Typically, 80% of your revenue comes from 20% of your products. These are your "A" items.

- Action for 2026: Never run out of these. These pay your mortgage. Your goal for 2026 is to increase the safety stock on these items so you don't stock out during supply chain hiccups.

Bucket B: The "Meh" (The Middle Class)

These sell consistently, but not spectacularly. They are the bread and butter. They keep the lights on, but they don't buy you a vacation.

- Action for 2026: Monitor them. Can you bundle them with "A" items to move them faster? Can you increase the price slightly to improve margin?

Speaking of margins, are yours actually healthy? Check out What Is a Good Profit Margin for a Small Business? (It Depends...)

Bucket C: The Dogs (The Ugly)

This is the stuff you found in the back corner covered in dust. The trendy item from 2024 that nobody wants anymore. The spare parts for a machine you sold.

- The Sunk Cost Fallacy: This is where small business owners lose money. You look at that pile of dead stock and think, "Well, I paid $1,000 for that, I can't just get rid of it."

- HatStacked Truth Bomb: Yes, you can. And you must. That stock is not an asset; it is a liability. It is taking up space that could be used for "A" items. It is costing you insurance. It is costing you mental energy.

- Action for 2026: Liquidation. Run a "New Year, Clean Warehouse" sale. 50% off. 70% off. Buy-One-Get-One. If that fails, donate it for the tax write-off. If that fails, throw it in the dumpster. Get the cash back, even if it’s pennies on the dollar, and move on.

Section 4: Forecasting 2026 (The Crystal Ball)

Now that we know what we have, we need to guess what we need.

Forecasting is essentially "Data-Driven Guessing." Nobody knows what 2026 holds. Maybe TikTok bans a color. Maybe a boat gets stuck in the Suez Canal (again). Maybe a new tariff makes your raw materials 20% more expensive overnight.

However, we can make educated guesses.

1. Lead Time Planning (The "Waiting Game")

In 2025, how long did it take for your supplier to get you goods?

If they said "30 days" but it actually took "45 days," update your system. You cannot plan inventory based on best-case scenarios. Plan for the reality.

- HatStacked Tip: If you import, add an extra 2 weeks of buffer stock for 2026. Global logistics are roughly as stable as a Jenga tower played by toddlers.

2. Safety Stock vs. Just-in-Time

For years, the MBA types preached "Just-in-Time" (JIT) inventory. The idea was to have the product arrive exactly when the customer bought it, keeping inventory costs at zero.

Then the 2020s happened. Then the supply chain broke.

JIT is dead for small businesses. We are now in the era of JIC (Just-in-Case).

You need Safety Stock. You need to calculate how much you sell in a week, multiply it by your lead time, and then add 20%. Yes, it ties up cash (see Section 1), but stockouts cost you customers forever.

3. Tariff-Proofing

If you source internationally, you are likely aware of the volatile tariff landscape.

- Strategic Buy-Ins: If you know a tariff hike is coming in Q1 2026, it might make sense to buy bulk inventory now (in late 2025) to lock in the lower price. This is a gamble on cash flow, but it protects your margins.

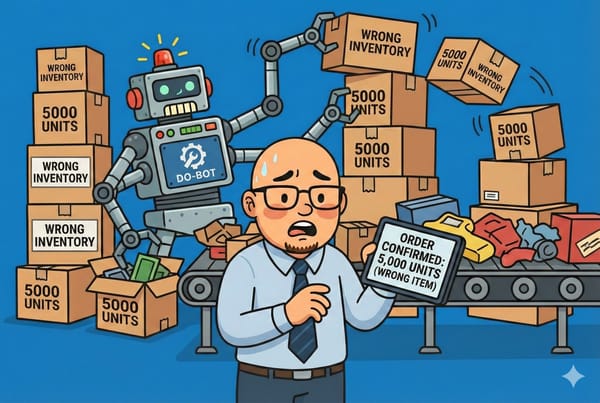

Section 5: The Tech Stack (Do I Need a Robot?)

Finally, let’s talk about how you track this.

If you are tracking $500,000 of inventory on a spreadsheet that you named Final_Inventory_v3_REAL_FINAL.xlsx, you are flirting with disaster.

The Spreadsheet Stage

If you are under $100k in revenue, Excel is fine. Spreadsheets are free and flexible. But spreadsheets don't talk to your Shopify store. They don't alert you when you're low on stock. They rely on you remembering to update them. And human memory is terrible.

The IMS Upgrade (Inventory Management System)

If you are scaling in 2026, it is time to invest in an IMS (Cin7, Katana, Zoho, etc.).

These tools act as the "Brain" of your operation.

- They sync your sales channels (Etsy, Amazon, Website) so when you sell one unit, it deducts from the master total.

- They calculate COGS automatically (saving you the Section 1 headache).

- They tell you when to reorder.

Is it expensive? Yes. Is it cheaper than paying your accountant to fix your mess in April? Also yes.

Still wondering if you need professional help? Read Do I Need a CPA for My Small Business, or Can I Keep Guessing?

Conclusion: Fold Up the Inventory Hat

Once the count is done, the data is entered, and the "Dogs" are put in the clearance bin, you can finally take a breath.

You have clarity.

You know your tax liability.

You know your liquidity.

You know what to buy in January.

You have mastered your stock. You are no longer flying blind. You have a map for 2026.

Now, go home. Eat some leftovers. Watch a movie. And try to forget what the inside of a cardboard box looks like for at least 48 hours.

Happy New Year, and may your 2026 cycle counts always match your system.

Keep your paper trail as clean as your warehouse. Read How to Organize Receipts for Small Business Without the Shoebox Method next.